The Importance of Choosing the Right RF PCB Manufacturer

High turnover high technology society means that printed circuit boards using advanced radio frequency (RF) is now mandatory. The three specialised PCBs are indispensable and critical in maintaining the optimal operation of devices and systems in use today.

So, as the sectors such as telecommunications, aerospace, healthcare devices, automotive technologies, etc, evolve the need for RF PCBs becomes more pertinent. The signal integrity and the reduction of interference make RF PCBs completely necessary when operating in such critical systems and applications.

Selecting the right RF PCB manufacturer is crucial for delivering the best performance, dependability and longevity of your projects. The following article discusses key considerations that should be made while choosing the manufacturer and explains why this is the key to business success.

Understanding RF PCBs and Their Applications

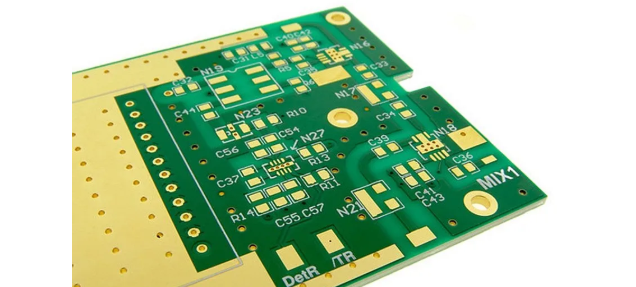

RF PCB is a kind of track and plane circuit board which specifically processes high-frequency signals or high-speed digital signals. RF boards’ specific characteristics do not allow signal attenuation and interference while providing identical performance at different frequencies, unlike reference PCBs.

These characteristics make RF PCBs crucial for applications like:

- Telecommunication Equipment: RF PCBs demonstrate extensive usage in mobile networks, satellite communication, and wireless devices for better data transmission.

- Aerospace and Defense: Military applications such as radar systems, communication devices and navigation tools require high-precision PCB RF designs.

- Medical Devices: RF PCBs are crucial for medical diagnostic imaging systems and wearable health monitoring devices for correct data interpretation.

- Automotive Systems: ADAS and V2X applications are vital to cross-system communication and need reliable low-loss RF PCB solutions.

Since these applications are sensitive, working with an Established RF PCB Manufacturer is important to get value-added products with high performance and quality.

Essential Considerations for Selecting an RF PCB Manufacturer

1. Expertise in RF Technology

There are challenging issues in the manufacturing of RF PCBs because of the high-frequency signal signal transmission. Look for a manufacturer with:

- Experience working with complicated radio frequency designs.

- Expertise with RF materials like PTFE, Rogers or ceramic substrate that don’t have much loss to signal.

- Capability of doing more advanced testing to check the RF performance efficiently.

2. Customization and Design Support

In exactly like manner, each given task or project will have some kind of specifications that they are going to follow. A reliable RF PCB manufacturer should offer:

- Custom design services for your application of the product.

- Cooperation with your engineers to get the best of the room layouts and the least of the interference of the signals.

- Prototyping services so that designers get an opportunity to tap into full-scale production.

3. Sophisticated Plants

RF PCB requires efficiency which is only feasible at modern production facilities with state-of-the-art machinery. Check for:

- Automation for building an assembly line for making components with high accuracy.

- Accurate testing equipment to help determine the effectiveness of equipment with high usage frequency.

- Decontamination zones are required to exclude contamination in the cleanroom environment.

4. Compliance with Industry Standards

To guarantee safety and performance, your RF PCB manufacturer must adhere to recognized industry standards such as:

- ISO 9001 for quality management is one of the seven key approaches recognized by the institute.

- Then, IPC standards applicable to PCB manufacturing are described.

- A key success factor is complying with RoHS regulations to avoid using hazardous substances in production.

5. Scalability and Lead Time

It is true that as the business advances, then it will be natural to need a larger production facility. Ensure the manufacturer can:

- Plan for growth in an effort to accommodate the ever-rising need for products.

- Meet the delivery schedules of products so within short times without downplaying quality.

6. Cost-Effectiveness

While maintaining quality is essential, securing competitive pricing is equally important. Evaluate quotes from various manufacturers to strike the right balance between affordability and excellence. Additionally, inquire about bulk order discounts and other cost-saving options.

Why Choose a Trusted RF PCB Manufacturer?

Collaborating with a reliable RF PCB manufacturer provides several key benefits:

- Enhanced Performance: The RF PCBs with high quality result in low signal loss and lesser interference hence enhancing device performance.

- Increased Reliability: A reliable manufacturer uses strong material and conducts tests on the PCBs, so that they can withstand all terrains.

- Faster Time-to-Market: Established manufacturers enhance their techniques in manufacturing hence resulting in short-time delivery of products.

- Reduced Costs: RF PCBs also cost significantly less amount of money than repairing faults that could be caused by low-quality boards at a later stage.

The Role of Additional Support Services

Many manufacturers go beyond production by offering value-added services, such as:

- Technical Consultation: Advice on choosing the right material for particular applications, on the ways of designing for minimum spending and on how to achieve the maximum spend within a given budget.

- Logistics Support: Services relating to forwarding of goods, customs clearance and stock handling.

- After-Sales Service: Immediate assistance and solution for the difficulties that occurred.

All the mentioned services can greatly add value to your experience and guarantee prolonged success.

Building Strong Partnerships with RF PCB Manufacturers

Selecting the right RF PCB manufacturer is critical and so is building a good relationship with them. The principles for successful collaboration in this setting are free-flowing communication, mutual openness and a common focus on quality. Communication can be weekly, bi-weekly or monthly, accompanied by feedback sessions and possible solutions for problematic areas can serve as an effective way to reach success.

In the selection of a manufacturer, it is also important to take into account additional services offered. For instance, most RF PCB firms also offer the services of PCB manufacturing and printed circuit board manufacturing. This means that with your company you can source all your needs thus cutting down on costs.

Conclusion

The choice of the RF PCB manufacturer is a very important consideration that can easily make or mar your projects. Even if you are not capable of performing detailed research on various options to select the right RF PCB supplier, a few general parameters always help to filter out the best one, including expertise, ability to customize PCB, and conformance to industry standards that will guarantee you that the boards you will receive will perform their functions optimally.

Furthermore, it is possible to benefit from the manufacturer facilitating adjacent services, thus, reducing costs and accelerating the process of development.

Regardless of the fact if you are involved in the production of modern communication devices or creating high-tech medical equipment, cooperation with the best RF PCB manufacturer is your ticket to success. If you want to improve your supply chain, feel free to check the PCB board manufacturer and other related services, including all the technological requirements in one place.