How Frameless Motor Enhances Power Density and Reliability

In today’s rapidly advancing industries—from robotics to electric vehicles—engineers are constantly seeking ways to improve efficiency, reduce weight, and maximize output. One of the most promising technologies driving this progress is the frameless motor. Unlike conventional housed motors, frameless motors are designed for direct integration into mechanical systems, offering a unique blend of flexibility, high torque density, and superior reliability.

This article explores how frameless motors work, their advantages over traditional motors, and why they’re becoming essential for high-performance applications where compactness, efficiency, and precision are key.

Understanding the Concept of a Frameless Motor

What Is a Frameless Motor?

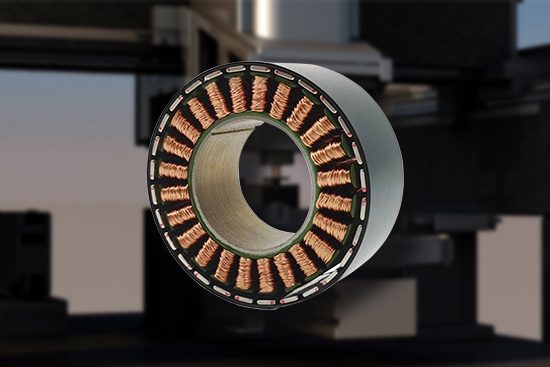

A frameless motor is essentially a motor without housing or bearings. It consists of two core components—the stator and the rotor—which are directly integrated into the mechanical structure of the application. This open-frame configuration allows designers to create custom systems that precisely match the motor’s capabilities with the machine’s specific requirements.

By removing unnecessary weight and components, frameless motors achieve higher efficiency and power density while reducing the total system size. This design is especially useful in applications like aerospace, medical devices, collaborative robots, and automation systems where every gram and millimeter count.

How It Differs from Traditional Motors

Traditional motors come in pre-packaged housings with built-in bearings and shafts. While this makes them easy to install, it also limits flexibility. Frameless motors, on the other hand, give engineers complete freedom to integrate the stator and rotor directly into their assembly. This means the mechanical design can be optimized for better alignment, heat dissipation, and load distribution.

Enhancing Power Density

High Torque in Compact Spaces

One of the most notable advantages of frameless motors is their exceptionally high power density. Since they lack a bulky outer casing, frameless motors can deliver more torque in a smaller volume. The absence of unnecessary material also improves heat management, which helps sustain continuous power output without overheating.

This makes them ideal for applications where space is limited but performance cannot be compromised—such as robotic arms, surgical tools, or drone propulsion systems.

Efficient Electromagnetic Design

The improved magnetic circuit of a frameless motor contributes directly to its superior torque-to-weight ratio. By using advanced winding configurations and high-grade magnetic materials, frameless motors reduce energy losses while maintaining high torque performance. The tighter coupling between rotor and stator improves responsiveness and dynamic control, enabling smoother operation even under variable loads.

Improving Reliability and Lifespan

Fewer Components, Fewer Failures

Reliability is one of the strongest selling points of frameless motors. With fewer mechanical parts like bearings, shafts, and housings, there are fewer potential points of failure. This simplifies maintenance and extends operational life.

In addition, since the motor is integrated directly into the host structure, vibration levels are lower, leading to reduced wear on components and improved stability during high-speed operations.

Better Thermal Management

Heat is the biggest enemy of electric motors. Traditional motors often struggle with internal heat buildup because their enclosed housings limit airflow. In contrast, frameless motors dissipate heat more efficiently due to their open design and customizable mounting options.

This improved thermal performance prevents overheating and extends the lifespan of both the motor and the surrounding mechanical components. Integrating liquid cooling or conductive materials into the system design can further enhance heat management for demanding applications.

Design Flexibility and Integration

Customization Opportunities

Because frameless motors are supplied as rotor-stator kits, engineers have the freedom to design custom housings, bearings, and shafts that best suit the target application. This flexibility allows for perfect alignment between mechanical and electrical systems.

For example, a robotic joint can be designed around the motor itself, maximizing available torque without wasting space. Similarly, in aerospace applications, frameless motors can be embedded directly into the airframe structure, reducing total weight while maintaining strength and efficiency.

Simplified System Architecture

Integrating a frameless motor directly into a machine reduces the need for additional couplings or mechanical adapters. This not only minimizes overall system complexity but also enhances accuracy and performance by reducing backlash and mechanical losses.

Simpler systems are inherently more reliable, easier to maintain, and lighter—attributes that are highly valued in next-generation technologies such as autonomous vehicles and precision robotics.

Applications Across Industries

Robotics

In robotics, compactness and motion precision are crucial. Frameless motors provide high torque in small packages, allowing for smoother and more responsive robotic motion. Their low inertia design improves control accuracy, which is particularly beneficial for collaborative robots and humanoid robots that operate alongside humans.

Aerospace and Defense

Weight reduction and efficiency are key priorities in aerospace engineering. Frameless motors enable lighter and more compact designs without sacrificing power. They can also withstand high thermal and mechanical stress, making them suitable for drones, satellites, and flight control systems.

Medical and Industrial Automation

In medical equipment, silent operation and precision are vital. Frameless motors are commonly used in surgical robots, imaging devices, and laboratory automation systems. Their smooth, vibration-free performance enhances both accuracy and safety in sensitive environments.

Industrial machines also benefit from their high efficiency and low maintenance needs, particularly in automated assembly lines and packaging systems.

Challenges in Implementing Frameless Motors

Alignment and Integration Precision

One of the main challenges in using frameless motors is achieving precise alignment between the rotor and stator during assembly. Misalignment can cause vibration, noise, or reduced efficiency. Therefore, accurate machining and specialized assembly jigs are essential.

Control System Compatibility

Frameless motors require customized control algorithms tailored to their electromagnetic properties. Engineers must carefully select compatible drives and motion controllers to ensure optimal performance. Once calibrated correctly, however, they deliver exceptional control and responsiveness.

The Future of Frameless Motor Technology

As industries continue to push for smaller, lighter, and more powerful machines, frameless motor technology will play a key role in the next generation of electromechanical systems. Advances in material science, cooling techniques, and electromagnetic design are further enhancing performance while reducing energy consumption.

With the growing adoption of automation, electric mobility, and smart manufacturing, the demand for frameless motors is expected to rise significantly. Their balance of high power density, flexibility, and reliability positions them as a cornerstone technology for the future.

Conclusion

The frameless motor represents a major step forward in motor design, enabling engineers to create compact, efficient, and high-performance systems tailored to specific needs. Its open architecture allows for optimal integration, superior heat management, and reduced mechanical complexity—key factors that enhance reliability and power output.

As innovation continues, the frameless BLDC motor stands out as a critical component in modern automation, robotics, and electric mobility. By combining precision engineering with flexibility, this motor type is redefining what’s possible in energy-efficient, high-performance machines—driving the future of motion technology toward greater power, reliability, and design freedom.